When Does A Co2 Detector Go Off?

Understanding CO2 Detectors: When and Why They Go Off

Carbon dioxide (CO2) detectors are critical safety devices designed to monitor levels of CO2 in your environment and alert you if concentrations reach unsafe thresholds. Though often overshadowed by carbon monoxide (CO) detectors, CO2 detectors serve an essential role in ensuring air quality, particularly in enclosed spaces where CO2 can accumulate unnoticed. People often ask, "When does a CO2 detector go off?" This question stems from an understandable concern for safety, as rising CO2 levels can have significant health implications. In this article, we’ll explore how CO2 detectors function, what triggers them, and practical ways to prevent unsafe CO2 levels in your home or workplace.

What Triggers a CO2 Detector?

CO2 detectors are calibrated to monitor the concentration of carbon dioxide in the air, typically measured in parts per million (ppm). A detector goes off when CO2 levels exceed a pre-set threshold, which is usually based on health and safety guidelines recommended by organizations like the Occupational Safety and Health Administration (OSHA), the Environmental Protection Agency (EPA), or the World Health Organization (WHO).

CO2 levels can rise for several reasons, including insufficient ventilation, combustion sources, and human activity, as we exhale carbon dioxide with every breath. High levels of CO2 can lead to symptoms ranging from mild discomfort to more severe issues such as headaches, fatigue, difficulty breathing, or even loss of consciousness in extreme cases. Here’s a breakdown of thresholds and potential health symptoms:

- 400–1,000 ppm: Typical indoor levels with good ventilation.

- 1,000–2,000 ppm: Poorly ventilated spaces may fall within this range, leading to drowsiness and a drop in focus.

- 2,000–5,000 ppm: Uncomfortable conditions with symptoms like headaches, dizziness, and restlessness.

- Above 5,000 ppm: This is considered the occupational exposure limit for an 8-hour workday. Prolonged exposure can lead to more harmful effects such as confusion or an increased heart rate.

- Above 40,000 ppm: Extremely hazardous; exposure for even a brief time can lead to severe health risks or asphyxiation.

CO2 detectors are pre-programmed to sound an alarm when specific danger thresholds are crossed, usually around 1,000 ppm for residential purposes and 5,000 ppm for industrial settings. This ensures that you have adequate warning to take action before levels become critical.

---

How Do CO2 Detectors Work?

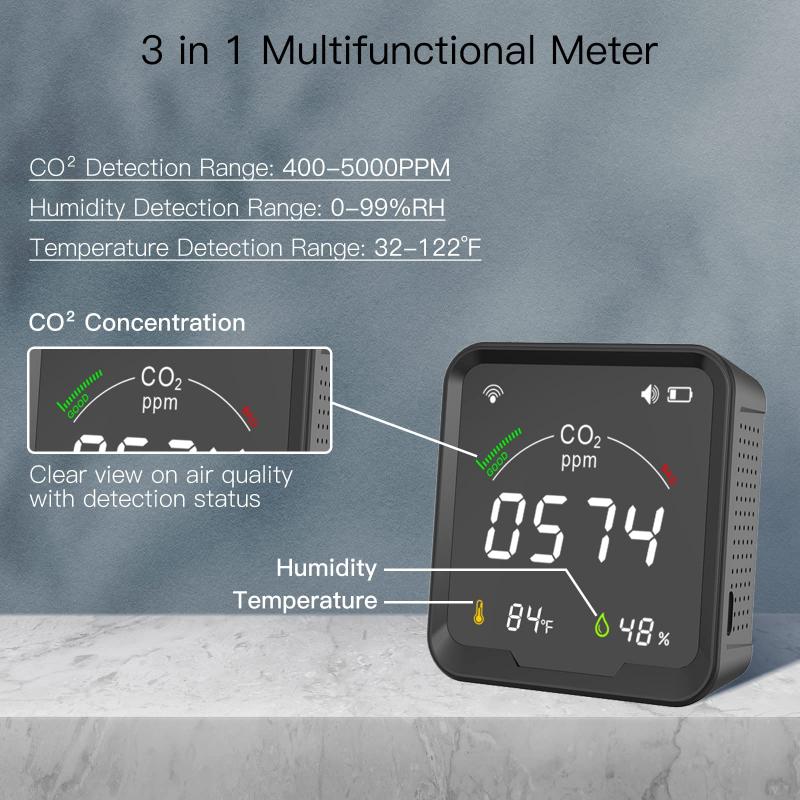

To understand when a CO2 detector will go off, it helps to know how the device operates. Most CO2 detectors employ infrared (IR) sensors, which work by measuring the absorption of infrared light by carbon dioxide molecules in the air. As the concentration of CO2 increases, so does the level of absorbed IR light, and an internal microprocessor in the detector calculates the exact CO2 level.

Some detectors also include additional features like temperature and humidity sensors to ensure more reliable readings, as changes in environmental conditions can impact CO2 concentration. Once the CO2 level crosses the detector's pre-set alarm threshold, an audible and/or visual alarm is triggered to warn occupants of the space.

Modern CO2 detectors may also come with the following features:

- Digital Display: Shows real-time CO2 levels.

- Connectivity: Smart detectors can pair with mobile apps for remote monitoring.

- Data Logs: For tracking air quality trends over time, often useful in workplaces or schools.

---

Common Scenarios Where CO2 Detectors May Go Off

1. Poor Ventilation in Occupied Spaces:

CO2 levels can rise quickly in enclosed, crowded spaces like conference rooms, classrooms, or public transportation if ventilation is inadequate. For example, a poorly ventilated bedroom overnight can result in levels crossing the 1,000 ppm mark due to human respiration.

2. Sealed Environments:

Homes with energy-efficient, airtight designs can inadvertently trap CO2. While energy efficiency is excellent for reducing utility costs, it can limit airflow, creating an environment where CO2 accumulates faster than it can dissipate.

3. Industrial or Commercial Settings:

CO2 alarms frequently go off in settings like breweries, greenhouses, or laboratories that use or produce CO2 as part of their operations. In such places, the threshold for the alarm is typically set higher, in alignment with OSHA guidelines.

4. Nearby Combustion Sources:

Gas appliances, heaters, and fireplaces release CO2 as a byproduct of combustion. Improperly ventilated combustion can lead to localized surges in CO2 levels.

5. Accidental Leaks:

In some industries—like food and beverage storage or dry ice handling—accidental CO2 leaks can elevate air concentrations to unsafe levels, prompting detector alarms.

---

What to Do When Your CO2 Detector Goes Off

1. Stay Calm and Assess the Situation:

Don’t panic. Check the detector's display (if available) to understand the CO2 levels. Many detectors also have a "low-level alarm" that activates before concentrations become dangerously high, so an early alert doesn’t necessarily indicate an immediate life-threatening emergency.

2. Ventilate the Area:

Open windows and doors to allow fresh air circulation. Use fans to help disperse the CO2 and lower the concentration quickly.

3. Evacuate if Necessary:

If CO2 levels are rapidly rising or the detector indicates hazardous conditions (e.g., a reading above 5,000 ppm), exit the space immediately and call for professional assistance. Prolonged exposure to high CO2 levels can have serious consequences.

4. Check Potential Sources:

Identify any possible contributors to elevated CO2 levels, such as malfunctioning ventilation systems, gas appliances, or heavy occupancy. If you suspect a leak or malfunction, turn off appliances and contact a professional to assess and resolve the issue.

5. Reset the Detector:

After addressing the issue and ventilating the area, reset the detector as per the manufacturer’s instructions. If the alarm sounds again shortly thereafter, monitor the space closely to ensure the problem has been fully resolved.

---

How to Prevent CO2 Alarm Events

To minimize the risk of your CO2 detector going off, consider implementing these preventative measures:

- Ensure Proper Ventilation: Regularly check that rooms, particularly high-traffic or enclosed areas, have adequate airflow. Installing exhaust fans or air exchangers can greatly improve ventilation and reduce indoor CO2 levels.

- Maintain Appliances: Properly maintain and inspect fuel-burning appliances, such as heaters or stoves, to ensure they are operating efficiently and not contributing to elevated CO2 levels.

- Monitor Air Quality: Use additional air quality monitoring devices alongside your CO2 detector to have a more comprehensive understanding of indoor pollutants.

- Be Mindful of Occupancy: Limit the number of people in enclosed spaces for extended periods, particularly if ventilation is limited.

- Educate Occupants: Raise awareness among family members, coworkers, or tenants about the importance of CO2 monitoring and how to respond to alarm events.

---

CO2 detectors are an essential tool for safeguarding air quality and promoting overall well-being in both residential and commercial environments. These devices generally go off when carbon dioxide concentrations exceed safe thresholds, providing you with crucial time to address the issue before it escalates. Understanding when and why a CO2 detector sounds an alarm—and knowing how to respond effectively—can protect you and others from potential health risks.

By embracing preventative measures such as ensuring proper ventilation, maintaining appliances, and minimizing sources of CO2 buildup, you can significantly reduce the likelihood of dangerous situations. If your CO2 detector sounds, consider it an opportunity to identify and address air quality issues proactively. With the right knowledge and tools, managing indoor CO2 levels becomes a straightforward task, creating safer and healthier spaces for everyone involved.