What Are Night Vision Goggles Made Of?

Night vision goggles are among the most fascinating technologies in modern optics. While they may seem like futuristic devices, their development and functionality are based on principles of physics and materials science. Understanding what night vision goggles are made of can offer insights into their operation, durability, and applications in military, scientific, and recreational fields. In this article, we will explore the underlying materials and components that enable night vision goggles to function effectively, and address some common questions about their use and applications.

Understanding Night Vision Goggles: The Science Behind the Technology

Night vision goggles (NVGs) are devices designed to enhance visibility in low-light conditions. This enhanced vision capability is primarily achieved through two methods: image intensification and thermal imaging. Each method relies on distinct materials and components, which we’ll explore in detail below.

At their core, the materials that make up night vision goggles are chosen for their ability to capture and manipulate light or heat. To better understand how these devices work, let’s discuss the key functional parts that make them so effective:

1. Objective Lens

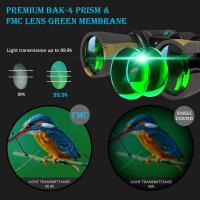

The objective lens is the first optical element in the night vision goggle assembly. Typically made of high-quality glass coated with anti-reflective materials, these lenses collect available ambient light from the surroundings, including light from stars, the moon, and even infrared emissions that are often invisible to the naked eye.

The coatings on these lenses ensure minimal light loss and maximize light transmission, which is critical in environments where illumination is scarce. In some high-end goggles, specialized materials such as fluorite glass are used to eliminate chromatic aberrations.

2. Image Intensifier Tube (for Image Intensification Goggles)

The image intensifier tube, arguably the most critical component in most night vision goggles, is a piece of technology that amplifies tiny amounts of ambient light. It is made of intricately layered materials:

- Photocathode: The photocathode is the heart of the image intensifier. Made from materials such as gallium arsenide (GaAs) or cesium-antimony compounds, it converts photons (light particles) into electrons. Gallium arsenide, in particular, is famous for its high sensitivity to infrared light, which makes modern NVGs significantly more effective than earlier models.

- Microchannel Plate (MCP): The MCP is a disk filled with millions of tiny channels that multiply the electrons generated by the photocathode. Made from glass or ceramic, these plates are often coated with a special resistive material to amplify the electrons as they pass through the plate. This multiplication ultimately ensures that even the faintest light becomes visible to the user.

- Phosphor Screen: After electron multiplication, the electrons strike a phosphor screen, converting them back into photons to generate a visible green image. Phosphor screens are usually composed of compounds like zinc sulfide doped with copper, which emits green light when excited by electrons. The green hue is not arbitrary; it’s selected because the human eye can distinguish more shades of green than any other color.

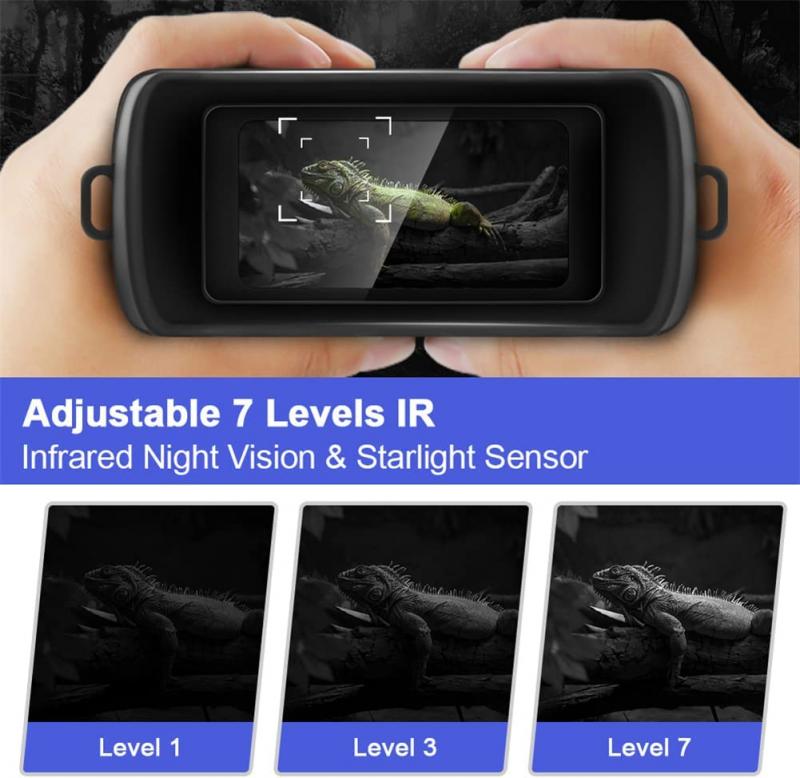

3. Infrared LEDs and Sensors (for Thermal Imaging Goggles)

Thermal imaging goggles, a separate class of night vision devices, don’t rely on amplifying visible light. Instead, they detect heat signatures. The materials used in thermal imaging systems are highly specialized:

- Microbolometer Detectors: These are typically made from materials such as vanadium oxide (VOx) or amorphous silicon (a-Si). These substances are sensitive to infrared radiation emitted by warm objects and convert it into an electrical signal.

- Germanium Lenses: Unlike glass, germanium can efficiently transmit infrared radiation, making it indispensable in thermal imaging systems. Polished germanium lenses focus the infrared light onto the detector.

4. Power Source

Without a power source, night vision goggles cannot function. NVGs rely on lightweight batteries made of lithium-ion or alkaline materials. These batteries power the image intensifiers, infrared illuminators, and any additional electronic components, ensuring that the device operates continuously for hours.

5. Housing and Frame

The materials in the outer casing of the goggles play a crucial role in durability and ergonomics. Military-grade night vision goggles are typically housed in rugged casings made of lightweight, shock-resistant polymers such as polycarbonate or fiberglass-reinforced plastics (e.g., Kevlar composites). These materials provide protection against impacts, extreme temperatures, and moisture, ensuring long life and reliability. Additionally, the ergonomic design of the frame uses lightweight metals like aluminum or magnesium alloys to ensure that the helmet-mounted or handheld goggles are comfortable during extended use.

Modern Variants and Technological Advancements

In recent years, advancements in materials science have led to the creation of night vision goggles that are lighter, more efficient, and capable of combining different technologies. A notable development is the fusion of image intensification and thermal imaging in the same device. To achieve this, engineers integrate delicate layers of material systems, which work in tandem to enhance vision in both light-starved and thermally active environments.

Another breakthrough involves the use of quantum dots for improving night vision performance. Quantum dots—tiny semiconductor particles only a few nanometers wide—can manipulate light across a wide spectrum. Some manufacturers are experimenting with quantum dot coatings for photocathodes and phosphor screens to achieve unprecedented levels of sensitivity and resolution.

Environmental Considerations in NVG Materials

As with most electronics, the manufacturing and disposal of night vision goggles pose environmental challenges. Certain compounds used in image intensifiers, such as gallium arsenide and cesium, are hazardous to handle and require careful recycling practices. Moreover, germanium, used in thermal imaging lenses, is a rare material, and its extraction is often an energy-intensive and environmentally taxing process. Future innovations may focus on finding more sustainable substitutes.

Applications of Night Vision Goggles

Understanding the materials that make up NVGs also provides insights into their diverse applications:

1. Military and Law Enforcement: Military-grade NVGs are crafted with advanced materials to perform reliably under the harshest conditions. Thermoplastic housings and shockproof components ensure they can withstand rugged environments and impacts during combat or rescue missions.

2. Wildlife Observation and Hunting: Night vision goggles used by scientists and hunters prioritize lightweight build materials for comfort during extended wear while integrating high-sensitivity image intensifiers to capture details of nocturnal fauna.

3. Personal Use and Security: With advancements lowering the manufacturing cost, NVGs are now available for recreational purposes or property security. While these typically lack the sophistication and durability of military models, they retain the same basic materials for functionality.

4. Aerospace and Navigation: Pilots and crews operating in low-visibility conditions rely on NVGs featuring cutting-edge optics and electronics, ensuring their materials meet the highest performance standards to avoid distortion at high speeds or altitudes.

Practical Considerations for Users

If you’re interested in purchasing or operating night vision goggles, your understanding of their materials can guide you in making an informed decision. For instance:

- Durability: Goggles with polycarbonate or fiberglass-reinforced housing are highly resistant to damage, making them suitable for challenging environments.

- Sensitivity: If you require extremely high sensitivity, opt for devices with gallium arsenide photocathodes or germanium lenses.

- Environmental Impact: Consider looking for manufacturers that address sustainability in their supply chain, particularly regarding rare or hazardous materials like gallium or germanium.

Final Thoughts

Night vision goggles are an extraordinary fusion of science, engineering, and design. From the image intensifier tube's complex arrangement of gallium arsenide to the durable yet lightweight polymer housing, every material plays a crucial role in enabling the device to turn darkness into light.

As technology continues to evolve, the materials and methods used in creating NVGs will undoubtedly become more advanced, lightweight, and environmentally conscious. Whether for professional, recreational, or personal use, understanding the components of these powerful tools can help users not only make educated choices but also appreciate the extraordinary science behind seeing in the dark.